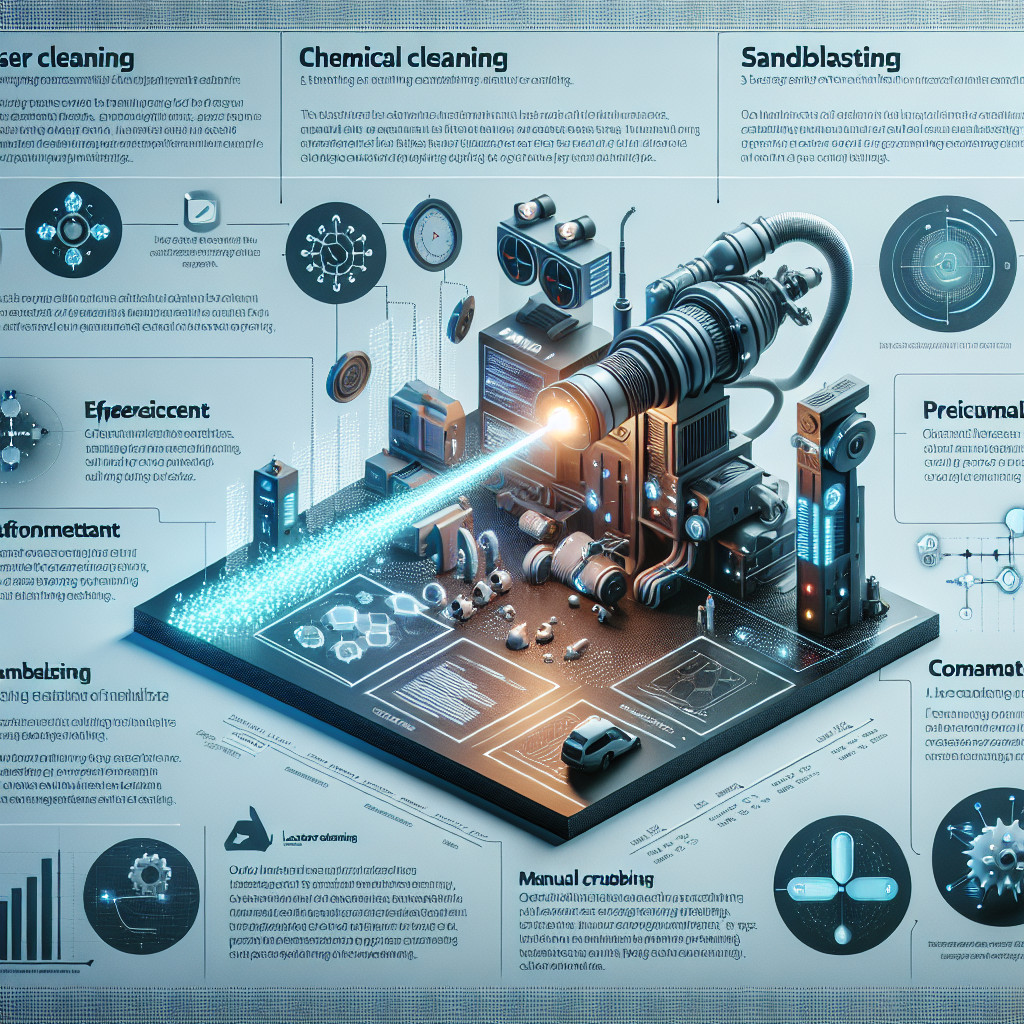

The advantages of laser cleaning over traditional cleaning methods

- Efficiency of laser cleaning

- Precision in laser cleaning

- Environmental benefits of laser cleaning

- Cost-effectiveness of laser cleaning

- Safety advantages of laser cleaning

Efficiency of laser cleaning

Benefits of laser cleaning:

- High precision: Laser cleaning allows for precise control over the cleaning process, ensuring that only the targeted material is removed without damaging the underlying surface.

- Environmentally friendly: Unlike traditional cleaning methods that use chemicals or abrasive materials, laser cleaning is a non-contact and chemical-free process, making it environmentally friendly.

- Cost-effective: While the initial investment in laser cleaning equipment may be higher than traditional methods, the long-term cost savings are significant due to reduced maintenance, labor, and waste disposal costs.

- Time-saving: Laser cleaning is a fast and efficient process that can be automated for continuous operation, saving time and increasing productivity.

Applications of laser cleaning:

- Automotive industry: Laser cleaning is used for removing paint, rust, and other contaminants from car bodies, engine components, and other parts.

- Aerospace industry: Laser cleaning is used for cleaning turbine blades, aircraft components, and other critical parts to ensure optimal performance and safety.

- Electronics industry: Laser cleaning is used for removing solder residues, coatings, and other contaminants from circuit boards and electronic components.

- Historical preservation: Laser cleaning is used for restoring and preserving historical artifacts, monuments, and buildings without causing damage to the original material.

Conclusion:

Laser cleaning is a highly efficient and versatile method of surface cleaning that offers numerous benefits over traditional cleaning methods. Its precision, environmental friendliness, cost-effectiveness, and time-saving properties make it an ideal choice for a wide range of industries and applications. As technology continues to advance, laser cleaning is expected to become even more efficient and widely adopted in the future.

Precision in laser cleaning

One of the key factors that determine the precision of laser cleaning is the selection of the appropriate laser parameters. The laser power and pulse duration are critical in determining the amount of energy delivered to the surface. Higher laser power and shorter pulse durations can result in more efficient cleaning but may also increase the risk of damaging the substrate. On the other hand, lower laser power and longer pulse durations may be less effective in removing contaminants but can reduce the risk of substrate damage.

Another important parameter in laser cleaning is the spot size of the laser beam. The spot size determines the area over which the laser energy is concentrated. A smaller spot size can provide higher precision in cleaning but may require more scanning passes to cover a larger area. On the other hand, a larger spot size can cover a larger area in a single pass but may result in less precise cleaning.

Scanning speed is another critical parameter in laser cleaning. The scanning speed determines how quickly the laser beam moves across the surface. A higher scanning speed can result in faster cleaning but may also reduce the precision of the process. Slower scanning speeds, on the other hand, can provide higher precision but may increase the overall cleaning time.

In addition to these parameters, the choice of laser wavelength can also impact the precision of laser cleaning. Different materials have different absorption properties at different wavelengths, so selecting the appropriate wavelength can optimize the cleaning process for specific applications. For example, shorter wavelengths are more effective for removing organic contaminants, while longer wavelengths are better suited for removing inorganic materials.

To illustrate the importance of these parameters in achieving , the following table provides a comparison of different laser cleaning parameters and their impact on the cleaning process:

| Parameter | Effect on Precision |

|---|---|

| Laser Power | Higher power can result in more efficient cleaning but may increase the risk of substrate damage |

| Pulse Duration | Shorter pulse durations can provide more precise cleaning but may also increase the risk of damage |

| Spot Size | Smaller spot sizes can provide higher precision but may require more scanning passes |

| Scanning Speed | Higher scanning speeds can result in faster cleaning but may reduce precision |

| Laser Wavelength | Choosing the appropriate wavelength can optimize cleaning for specific materials |

In conclusion, achieving requires careful control of various parameters such as laser power, pulse duration, spot size, scanning speed, and laser wavelength. By selecting the appropriate parameters for specific applications, manufacturers can optimize the cleaning process to achieve high precision without damaging the substrate. This can result in improved efficiency, quality, and cost-effectiveness in industrial cleaning processes.

Environmental benefits of laser cleaning

Reduced chemical usage

One of the primary environmental benefits of laser cleaning is the reduction in chemical usage. Traditional cleaning methods often rely on harsh chemicals that can be harmful to both human health and the environment. By using lasers to clean surfaces, there is no need for these chemicals, leading to a significant reduction in hazardous waste and pollution.

Energy efficiency

Laser cleaning is also more energy-efficient than many traditional cleaning methods. The energy required to power a laser is typically lower than the energy needed to operate equipment for chemical cleaning or abrasive blasting. This results in lower energy consumption and reduced greenhouse gas emissions.

Minimal waste generation

Another environmental benefit of laser cleaning is the minimal waste generation. Traditional cleaning methods often produce large amounts of waste in the form of contaminated water, sludge, or abrasive materials. Laser cleaning, on the other hand, produces minimal waste as the contaminants are vaporized or ablated from the surface, leaving behind clean surfaces and no additional waste to dispose of.

Reduced water usage

Many traditional cleaning methods require the use of water for cleaning and rinsing surfaces. Laser cleaning, however, is a dry process that does not require water. This results in significant water savings and reduces the strain on water resources, especially in areas experiencing water scarcity or drought conditions.

Improved air quality

Chemical cleaning and abrasive blasting can release harmful fumes, dust, and particulate matter into the air, contributing to air pollution and respiratory problems. Laser cleaning, on the other hand, produces minimal airborne contaminants, leading to improved air quality and a healthier work environment for operators and nearby residents.

Conclusion

In conclusion, laser cleaning offers several environmental benefits compared to traditional cleaning methods. From reduced chemical usage and energy efficiency to minimal waste generation and improved air quality, laser cleaning is a more sustainable and eco-friendly option for surface cleaning and restoration. As industries and businesses increasingly prioritize environmental sustainability, laser cleaning is becoming a preferred choice for achieving clean and environmentally friendly results.

Cost-effectiveness of laser cleaning

Laser cleaning is a technology that has been gaining popularity in recent years due to its efficiency and effectiveness in removing contaminants from various surfaces. This method uses a high-powered laser beam to vaporize or ablate the unwanted material, leaving behind a clean surface without the need for chemicals or abrasive materials.

One of the key advantages of laser cleaning is its cost-effectiveness. While the initial investment in a laser cleaning system may be higher than traditional cleaning methods, the long-term savings can be significant. Here are some reasons why laser cleaning is a cost-effective solution:

1. Reduced labor costs: Laser cleaning is a highly automated process that requires minimal human intervention. This means that fewer workers are needed to operate the equipment, leading to lower labor costs in the long run.

2. Elimination of consumables: Unlike traditional cleaning methods that require the use of chemicals, solvents, or abrasive materials, laser cleaning does not rely on consumables. This eliminates the ongoing costs associated with purchasing and disposing of these materials.

3. Increased efficiency: Laser cleaning is a fast and efficient process that can remove contaminants quickly and effectively. This means that less time is required to clean a surface, resulting in increased productivity and cost savings.

4. Reduced maintenance costs: Laser cleaning systems are designed to be durable and require minimal maintenance. This reduces the need for costly repairs or replacements, further contributing to cost savings over time.

5. Environmental benefits: Laser cleaning is a clean and environmentally friendly process that does not produce harmful fumes or waste. This can lead to cost savings in terms of compliance with environmental regulations and disposal costs.

In addition to these cost-saving benefits, laser cleaning also offers other advantages such as precision cleaning, non-contact operation, and the ability to clean delicate or hard-to-reach surfaces. These factors make laser cleaning a versatile and efficient solution for a wide range of applications in industries such as automotive, aerospace, electronics, and more.

Overall, the makes it a compelling choice for businesses looking to improve their cleaning processes while reducing costs in the long term. With its efficiency, effectiveness, and environmental benefits, laser cleaning is a technology that is likely to continue to grow in popularity in the years to come.

Summary:

– Laser cleaning is a cost-effective solution for removing contaminants from surfaces.

– The technology offers reduced labor costs, elimination of consumables, increased efficiency, and reduced maintenance costs.

– Laser cleaning is environmentally friendly and offers other advantages such as precision cleaning and non-contact operation.

– Businesses can benefit from the cost savings and efficiency of laser cleaning in a variety of industries.

Safety advantages of laser cleaning

1. Non-contact cleaning

One of the key safety advantages of laser cleaning is that it is a non-contact method. This means that the laser beam does not physically touch the surface being cleaned, reducing the risk of damage to delicate materials or surfaces. In contrast, traditional cleaning methods such as sandblasting can cause abrasion or pitting on the surface, leading to potential safety hazards.

2. No use of chemicals

Another safety advantage of laser cleaning is that it does not require the use of chemicals or solvents. This eliminates the risk of exposure to harmful fumes or toxic substances, making it a safer option for both workers and the environment. In addition, laser cleaning is a more environmentally friendly method as it does not produce hazardous waste that needs to be disposed of properly.

3. Precision cleaning

Laser cleaning offers a high level of precision, allowing for targeted cleaning of specific areas without affecting surrounding surfaces. This reduces the risk of accidental damage or over-cleaning, which can occur with traditional methods. The ability to control the intensity and focus of the laser beam ensures that only the desired contaminants are removed, improving safety and efficiency.

4. Reduced risk of fire hazards

Traditional cleaning methods such as sandblasting or chemical cleaning can generate heat and sparks, increasing the risk of fire hazards in industrial settings. Laser cleaning, on the other hand, produces minimal heat and does not create sparks, reducing the risk of fires or explosions. This makes it a safer option for cleaning flammable materials or in environments where fire safety is a concern.

5. Operator safety

Laser cleaning systems are designed with safety features to protect operators from potential hazards. These include interlocks, safety sensors, and protective enclosures to prevent accidental exposure to the laser beam. Training and certification are also required for operators to ensure safe handling of the equipment. By following proper safety protocols, the risk of injuries or accidents during laser cleaning operations can be minimized.

Conclusion

In conclusion, laser cleaning offers several safety advantages over traditional cleaning methods. Its non-contact nature, lack of chemicals, precision cleaning capabilities, reduced fire hazards, and operator safety features make it a preferred choice for industries looking to improve safety and efficiency in their cleaning processes. As technology continues to advance, laser cleaning is expected to become even more widely adopted in various applications.